Soda Ash for Tunneling

Sodium Carbonate, or Soda Ash is a dry granular particle used to adjust the pH of water, drilling fluid, or slurry. The use of Soda Ash to adjust the pH of the makeup water can optimize the performance of drilling fluids, bentonite, and polymer slurries.

Adjusts the pH of water. Used in the production of containers, glass, commercial building materials, and automotive parts.

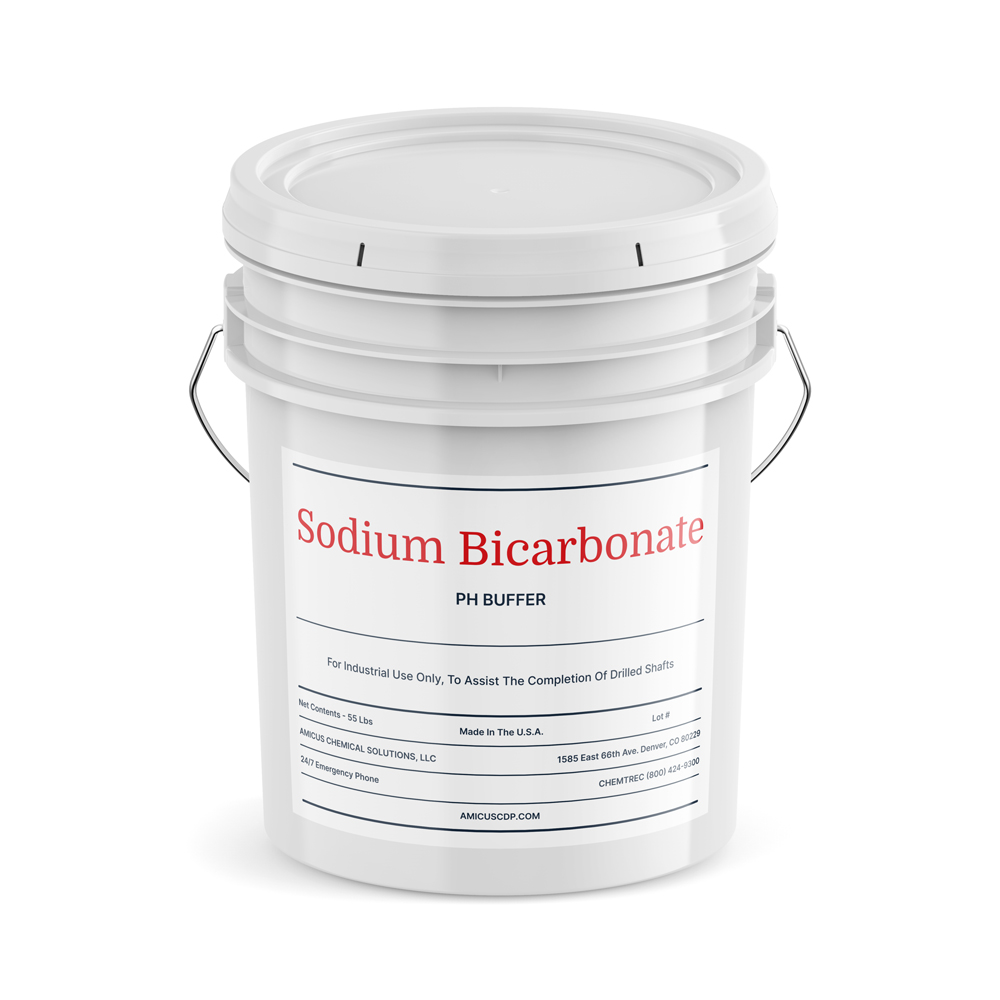

Bulk, 2000 lb bulk bags, 50 lb bags, and 5 gallon buckets.

The addition of Soda Ash to water adjusts the pH to the desired level. When used in a drilling or construction application, it adjusts the makeup water to the desired level, so the bentonite and polymer will hydrate properly, generating maximum performance.

Sand, rock, and gravel.

Soda Ash for Tunneling

Soda ash, scientifically known as sodium carbonate, plays a significant role in the tunneling industry, primarily due to its unique chemical properties and versatility. When used in tunneling operations, soda ash serves multiple functions, including as an additive in cement formulations, stabilizer for soil, and even as a pH modifier in various drilling fluids. Its ability to improve the workability of concrete makes it a valuable ingredient when creating tunnel linings and other structural elements. Moreover, soda ash can enhance the durability of cement by increasing its resistance to alkali-silica reactions, contributing to the longevity of underground structures.

The application of soda ash also extends to environmental management within tunneling projects. It aids in mitigating the effects of acidity that can arise from soil and rock interactions during excavation. By adjusting pH levels, soda ash helps in preventing erosion and degradation, ensuring a more stable environment for construction. This capability not only enhances the safety and stability of tunnels but also aligns with sustainable practices in the tunneling industry. As the demand for infrastructure grows, the use of soda ash in tunneling showcases an innovative and effective approach to modern engineering challenges.

Advantages of Soda Ash

Soda ash, also known as sodium carbonate, plays a crucial role in tunneling projects by effectively adjusting the pH levels of water used during the excavation and construction processes. Maintaining a balanced pH is essential for optimizing the performance of water used in various applications, such as soil stabilization and excavation support.

By introducing soda ash into the water, construction teams can neutralize acidic conditions that may compromise the stability of the tunneling environment. This adjustment not only enhances the effectiveness of additives employed in the tunneling process but also ensures that the materials used in construction maintain their integrity and durability, ultimately leading to safer and more efficient project outcomes.

Beyond its utility in tunneling projects, soda ash is a vital component in the manufacturing of various products, including glass, commercial building materials, and automotive parts. Its properties make it an indispensable ingredient in the production of containers and structural components, as it contributes to the strength and clarity of glass products. In addition, soda ash is utilized in creating building materials like concrete and ceramics, enhancing their quality and longevity.

This multi-faceted application of soda ash not only underscores its importance in the construction industry but also highlights its relevance in fostering sustainable practices by promoting the use of durable materials. As tunneling projects progress, leveraging soda ash can lead to improved project efficiency while supporting the broader goals of sustainability and innovation in construction.

Why use Soda Ash

The utilization of soda ash, or sodium carbonate, in water treatment plays a critical role in achieving optimal pH levels, particularly in drilling and construction applications. By adding soda ash to water, professionals can effectively adjust the pH to a desired range, which is essential for the proper hydration of drilling fluids and additives such as bentonite and polymers.

These materials, widely used in drilling processes, require specific chemical environments to perform efficiently. The right pH not only enhances their hydration but also ensures that they can function effectively, improving the overall performance of the drilling operations.

In practice, the incorporation of soda ash into the makeup water serves to facilitate a more stable and productive drilling environment. Properly hydrated bentonite and polymers exhibit enhanced viscosity, fluid loss control, and borehole stability, which are vital for the success of any construction project. By maintaining the correct pH levels through the careful addition of soda ash, professionals can optimize the performance of these materials, thereby increasing the efficiency and effectiveness of drilling operations.

This strategic application of soda ash not only supports the technical requirements of drilling but also contributes to a smoother workflow, reducing the risk of complications and delays during construction activities.

Proper Soil Conditions for Soda Ash in Tunneling Projects:

In tunneling projects, the proper soil conditions are crucial for the effective application of soda ash as a stabilizing agent. Soda ash serves multiple purposes, including pH adjustment and moisture balance, which enhance the integrity of the soil and surrounding structures.

Ideally, the soil composition should consist of sand, rock, and gravel, as these materials collectively provide the necessary permeability and drainage characteristics. Sand, with its granular nature, allows for the easy movement of water and air, facilitating the reaction of soda ash with the soil components. When combined with gravel and larger rock particles, this mixture contributes to a stable environment that can better withstand the pressures exerted during tunneling activities.

The effectiveness of soda ash in stabilizing sand, rock, and gravel mixtures hinges on maintaining optimal moisture levels and ensuring sufficient compaction. When these materials are well compacted, they reduce the likelihood of soil collapse and create a stronger support system for the tunnel structure.

Additionally, the interaction between soda ash and the soil promotes a process known as agglomeration, where particles bind together, enhancing the overall cohesiveness of the mixture. Thus, when employed in the right conditions, soda ash significantly contributes to the long-term stability and safety of tunneling projects, making an understanding of soil composition and management practices essential for engineers and construction professionals alike.

We're committed to quality.

Integrity

With strong moral principles and the will to get things done right, the sky is truly the limit.

Trust

Earning it daily with every conversation, handshake, E-mail, and phone call.

Innovation

Our eagerness to create, design, and solve the next great challenge that comes our way.